Sick C4000 Safety light curtain

|

The sick c4000 safety light curtain is used to secure the working area of the robot. This device ensures that the robot will stop if a person or object enters the working area. This document applies when troubleshooting the system in case it does not work properly. |

|

This is a safety device. To be used by trained and authorized personnel only. |

1. Use following tools

|

|

2. Description

2.1. Indications

The 'light-curtain system' existst out of two seperate devices: a sender and a reciever.Sender and reciever can be identified by markings which are located between the status indicator lights and the 7-segment display.

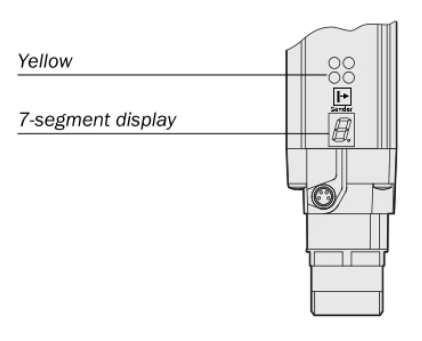

2.1.1. Sender

Yellow The Supply voltage is OK

7-segment display See further: 'display messages'

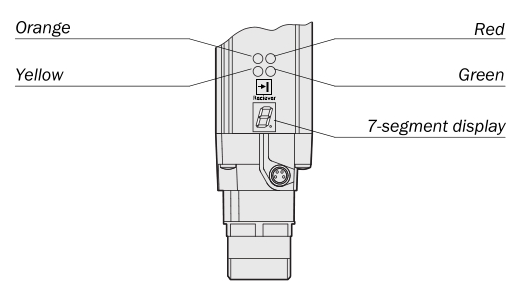

2.1.2. Receiver

Orange Cleaning or realignment required

Yellow Reset required (on C4000 Guest has no function, this light typically isn’t used in RoboJob systems)

Red System providing signals for shutting down the machine (switching output off)

Green System enabled (switching output on)

7-segment display See further: 'display messages'

2.2. First diagnostics

Make sure the screens of both sender and reciever are clean:

-

Use a clean and soft brush to remove dust from the front screen

-

Wipe the front screen with a clean and damp cloth

-

Do not use aggressive or abrasive cleaning agents!

While cleaning the sender and reciever, make sure to not affect their positions as this could break their alignment.

Check if there are any obstructions between the sender and reciever. Obstacles are not always clearly visible. Some things that often are overlooked:

-

Cables or air tubes

-

Clouds of dense coolant-mist that seem transparent to the eye

-

Reflectors outside the safety zones

-

Insects or animals

In normal working conditions, the following indicator lights should be illuminated:

Sender:

-

Yellow (voltage pressent)

Reciever:

-

Green (system enabled, this means that the light curtain isn’t interrupted)Be aware: this doesn’t mean the robot is ready to start, it is possible that the light screen still has to be reset using the blinking yellow reset button near the IPC.

2.3. Display messages

|

|

The receiver cannot synchronise with the sender; the alignment is very poor. |

|

|

Some light beams do not hit the receiver. |

|

|

All the light beams hit the receiver, but the alignment is still slightly off. |

|

|

The alignment is true; the devices must be locked in this position. |

|

Other error messages |

See chapter 10.4 of the C4000 operating manuel. |

The following chapters are relevant for maintenance and fault diagnosis.

-

9 Care and maintenance

-

10 Fault diagnosis

3. How to get further help

Do not hesitate to contact us when you need additional support beyond the documents provided in the RoboJob Service Knowledge Base.

You may contact the RoboJob Service department using following means:

-

Help Center: service.robojob.eu

-

Email: service@robojob.eu

-

Phone: +32 15 70 89 70

We kindly ask you to provide us the following information:

-

Serial number xx-xx-xxx

-

Description of the fault or defective part

-

Exact error code or message

-

What did the robot do

-

What was the robot supposed to do

-

Pictures or videos

You can send this information to us via email.To send large files you may make use of a file transfer service like WeTransfer: robojob.wetransfer.com.

An automatic confirmation will be sent upon receipt of your mail.