How to move the tower elevator manually

|

This document describes how you can move the elevators of the Tower manually. |

|

If you are experiencing problems that prevent the lift from moving automatically, it is advised to first contact the RoboJob service department before trying the procedure in this document. |

1. Use following tools

|

|

|

|

2. Procedure

2.1. Preparation

Before starting, Cancel any scheduled jobs in the software.This way, there is no possibility for the software to send commands to the tower.

2.2. Turn off belt sensors

If the software gives the alarm LX-07: Lift Alarm: Belt-Stop, you need to turn off the belt sensors first.If the error is not present, leave the belt sensors on.

To disable the sensors, go to the electrical cabinet under the tower.In most cases, this is located under the elevator on the robot side.

In the electrical cabinet is a Switch next to the PLC.

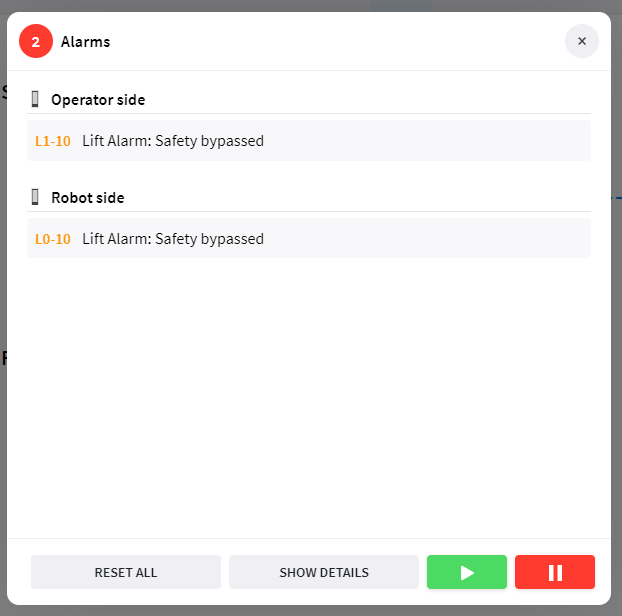

After disabling the belt sensor, An error LX-10 shows up that the safety is bypassed.If this error is given, this means you did it correctly.

|

Safety Bypassed only includes the belt sensors. Light curtains or fencing can still prevent the elevator from moving. |

2.3. Moving the elevators

2.3.1. Resetting all errors

Before the elevators can be moved, all errors must be reset.

If you have disabled the belt sensors, the LX-10 error cannot be reset.This error does not prevent the elevators from moving.

2.3.2. Using the handheld

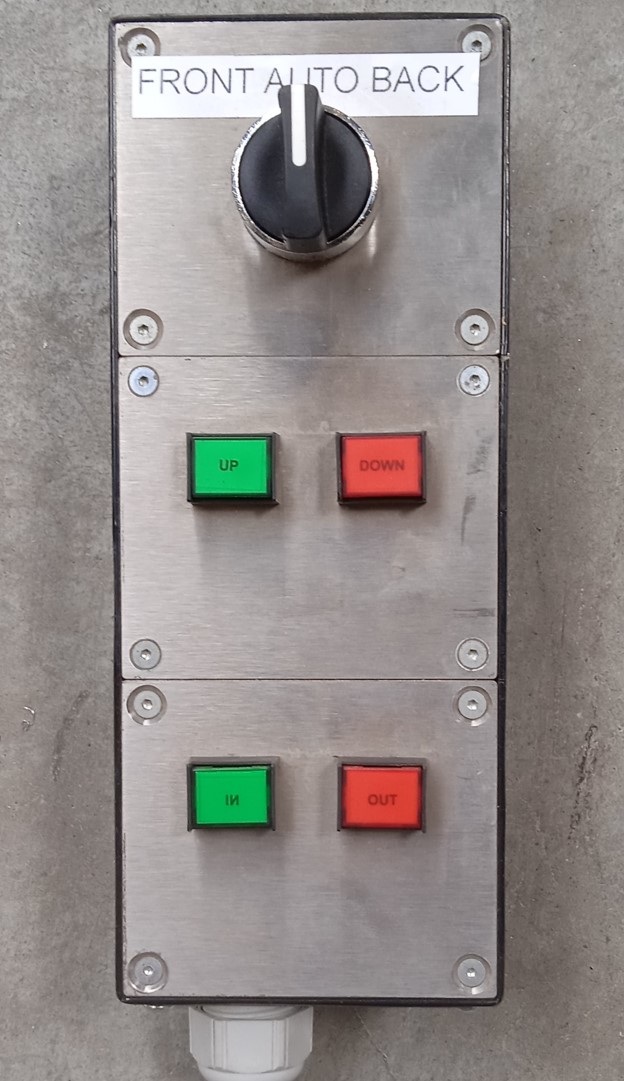

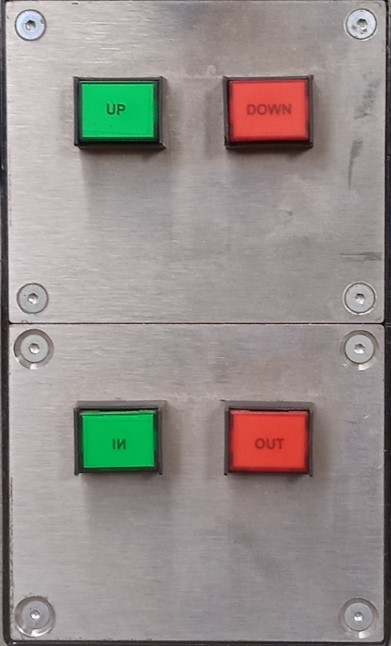

There are 3 modes on the handheld.

-

FRONT:Front lets you control the elevator on the robot side.

-

AUTO:Auto won’t let you move anything, but gives the control to the TowerPLC.

-

BACK:Back lets you control the elevator on the operator side.

-

Up and down is for vertical movement.

-

In and out is for horizontal movement.

|

If the elevator is not moving when you expect it to, it could be that there is an error.Check the error screen for errors and try resetting then. |

3. How to get further help

Do not hesitate to contact us when you need additional support beyond the documents provided in the RoboJob Service Knowledge Base.

You may contact the RoboJob Service department using following means:

-

Help Center: service.robojob.eu

-

Email: service@robojob.eu

-

Phone: +32 15 70 89 70

We kindly ask you to provide us the following information:

-

Serial number xx-xx-xxx

-

Description of the fault or defective part

-

Exact error code or message

-

What did the robot do

-

What was the robot supposed to do

-

Pictures or videos

You can send this information to us via email.To send large files you may make use of a file transfer service like WeTransfer: robojob.wetransfer.com.

An automatic confirmation will be sent upon receipt of your mail.