Disconnect gripper cable and disable sensors in the software

|

The sensors in the gripper aren’t working anymore and the gripper cable has to be removed to prevent a short circuit in the robot.furthermore, some adjustments have to be made to disable the sensors by software. |

1. Use following tools

|

|

|

2. Procedure

2.1. Disconnect the cable

2.1.1. Remove cover Pneubox

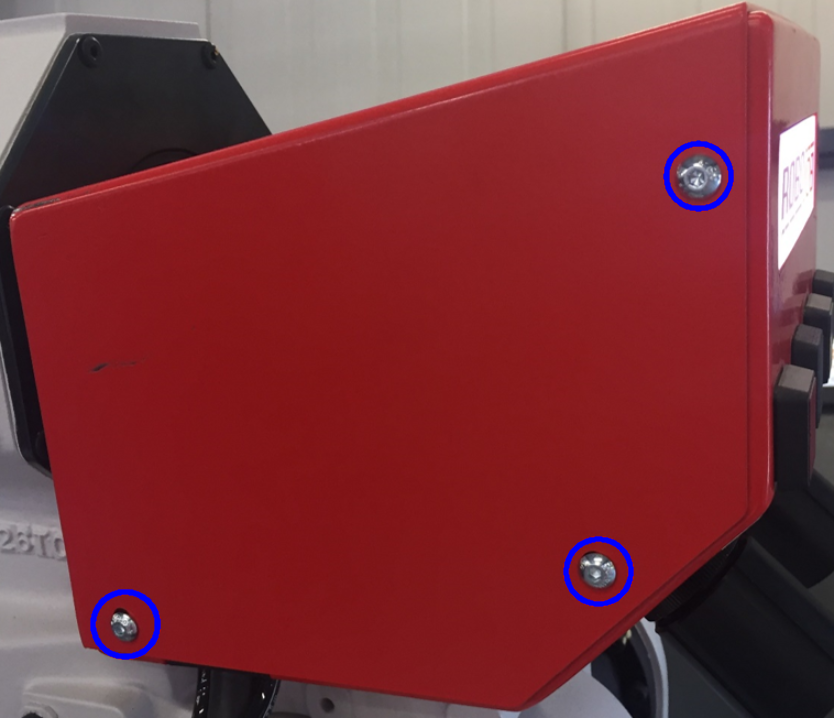

To get access to the gripper cable, the cover of the Pneubox needs te be removed.This can be done by unscrewing the bolts on both sides of the Pneubox.

2.1.2. Unplug the cable

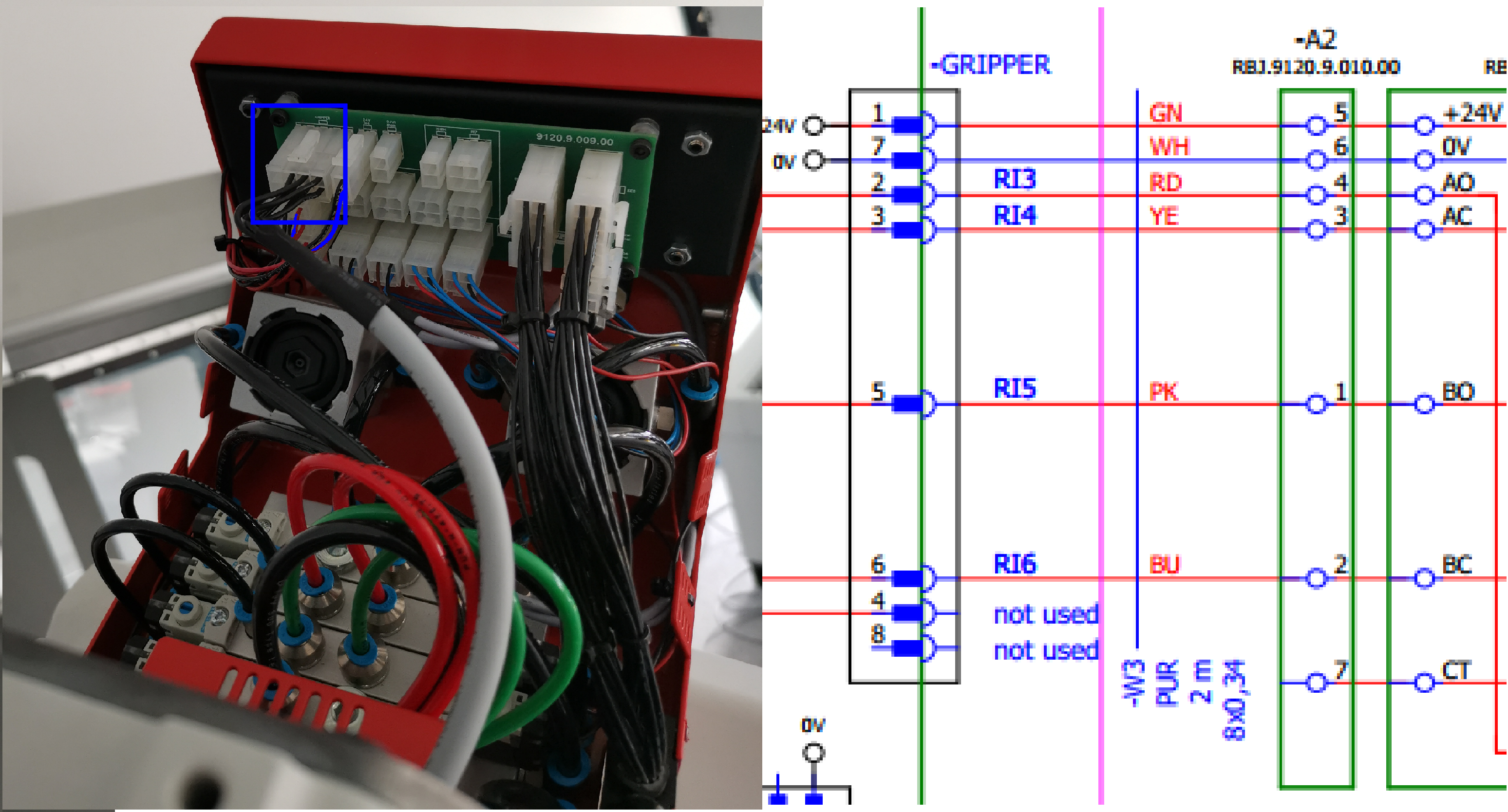

With the cover removed the PCB’s are visible.The plug of the gripper cable is located in the top left corner of the inside of the Pneubox with inscription Gripper above.

For the older versions all 6 wires are the same colour with numbers on them.The numbers on the left are from the plug, the numbers on the right are from the cable.On the newer versions the wires are colourcoded.The numbers on the left are from the plug, the colours are indicated above the drawn wires.

Now it is possible to unplug the gripper cable out of the PCB.

2.1.3. Install cover Pneubox

With the cable unplugged, the cover of the Pneubox can be reinstalled.To do this the bolts must be screwed back into place.

2.2. Disable the sensors in the Software

-

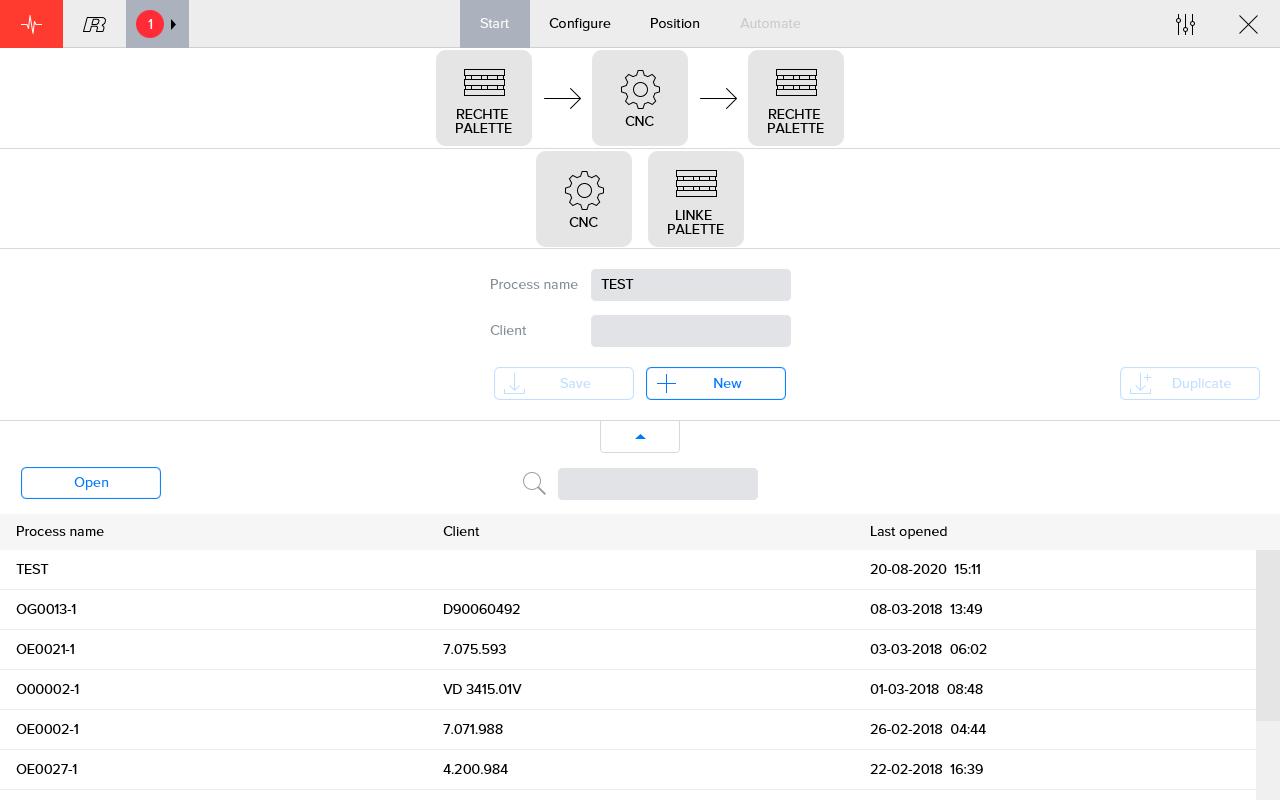

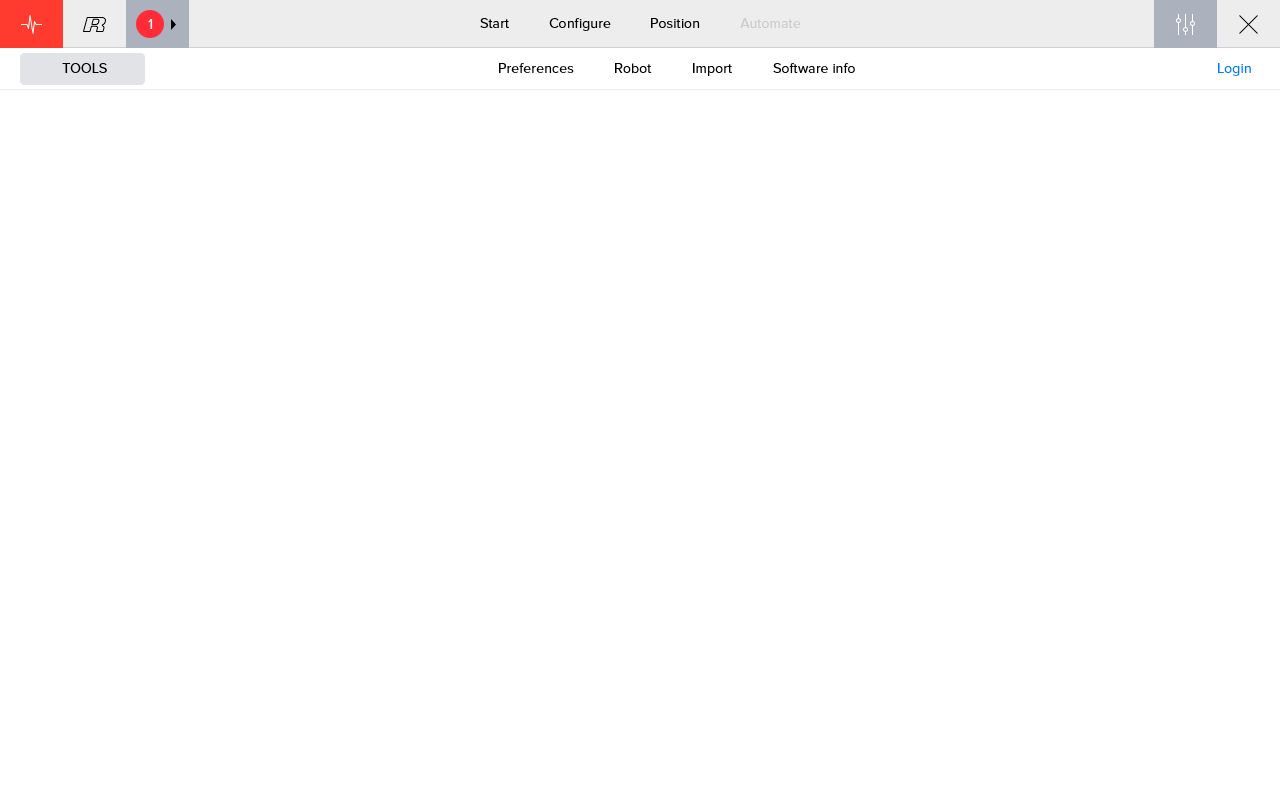

Open the Multi-Assist Software.

-

Open the settings menu by pressing the Settings-button in the top right corner.

-

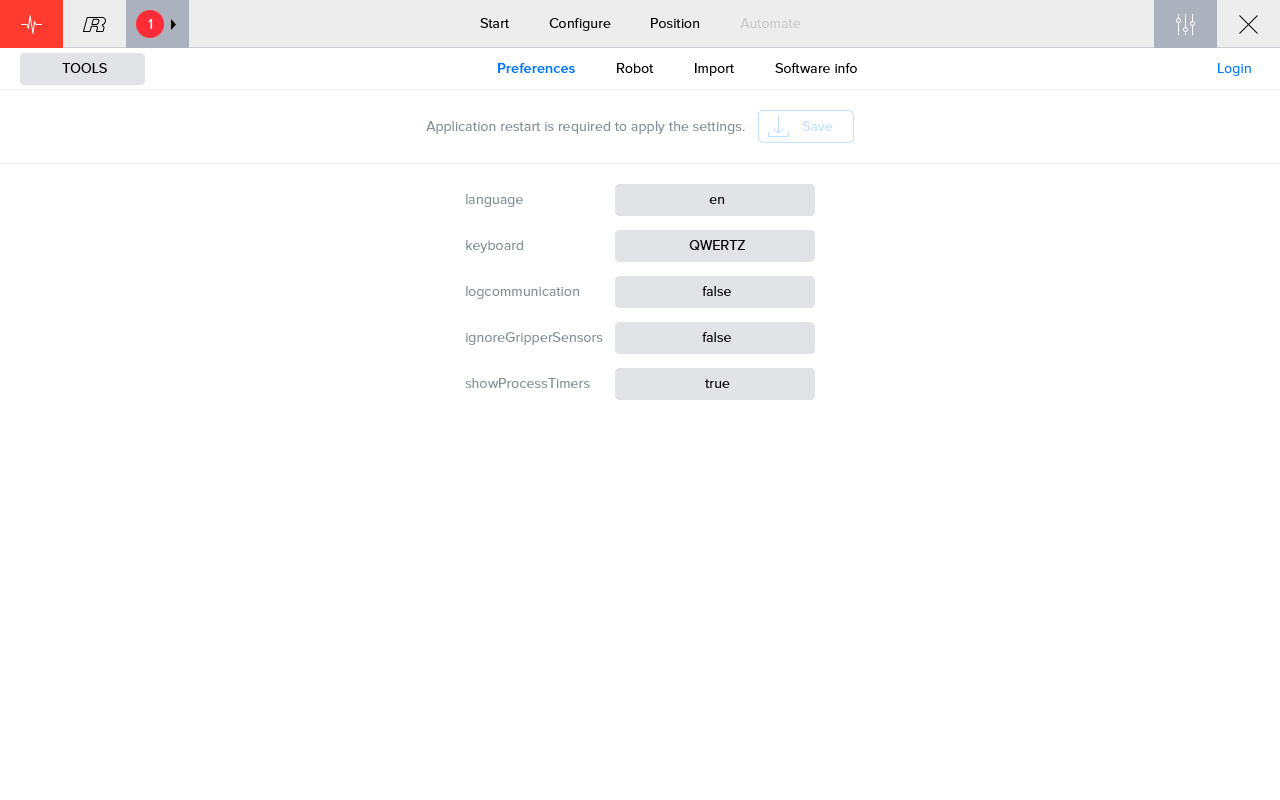

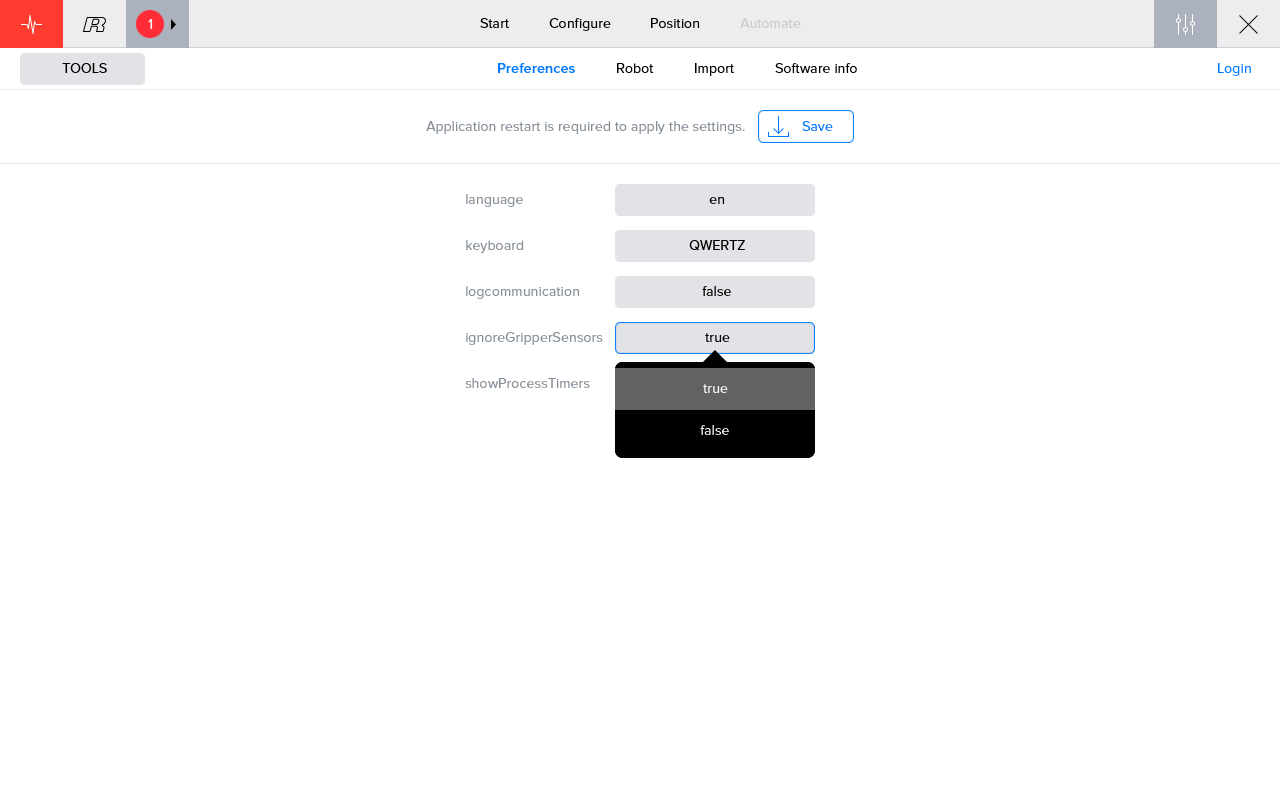

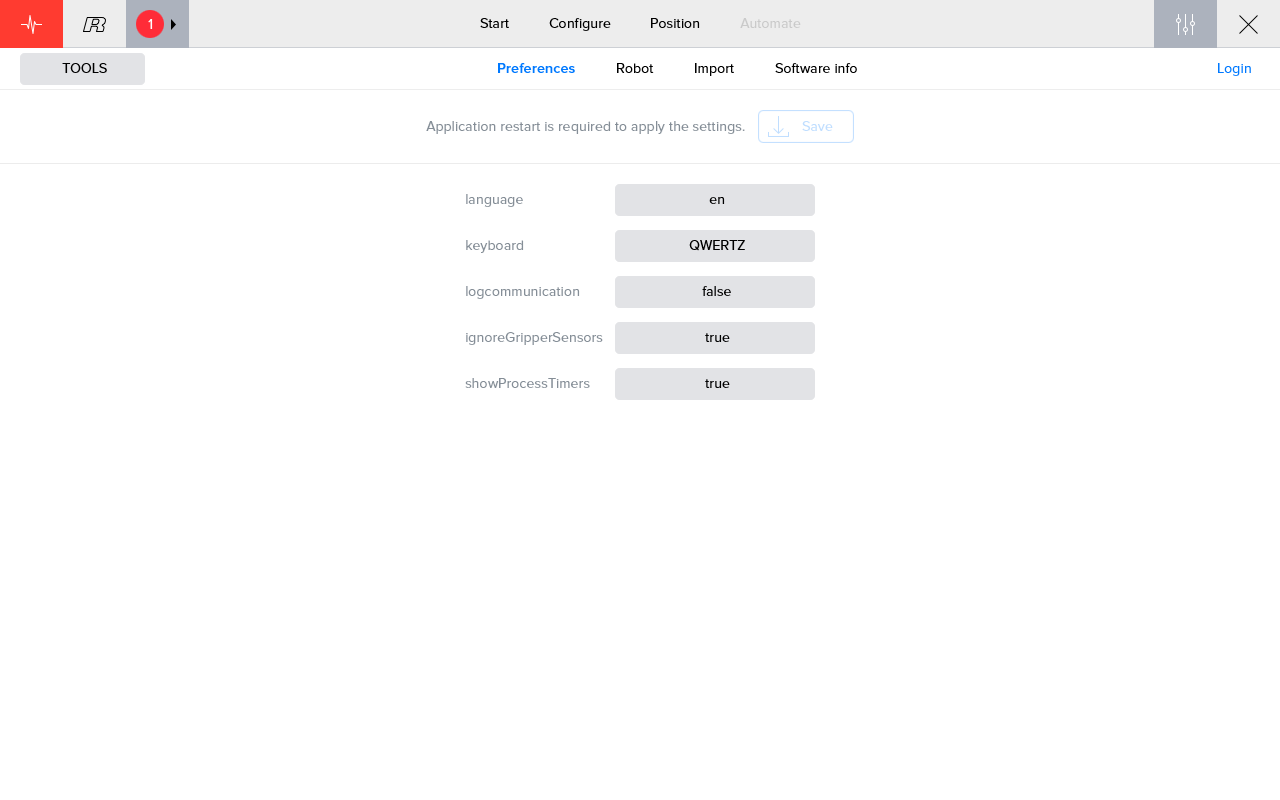

Open the Preferences-menu.

-

Change the setting IgnoreGripperSensor to True.

-

Save the changes by pressing the Save-button in the middle of the screen.

3. How to get further help

Do not hesitate to contact us when you need additional support beyond the documents provided in the RoboJob Service Knowledge Base.

You may contact the RoboJob Service department using following means:

-

Help Center: service.robojob.eu

-

Email: service@robojob.eu

-

Phone: +32 15 70 89 70

We kindly ask you to provide us the following information:

-

Serial number xx-xx-xxx

-

Description of the fault or defective part

-

Exact error code or message

-

What did the robot do

-

What was the robot supposed to do

-

Pictures or videos

You can send this information to us via email.To send large files you may make use of a file transfer service like WeTransfer: robojob.wetransfer.com.

An automatic confirmation will be sent upon receipt of your mail.