Adjust the axis-edge detection laser

|

Due to vibrations over a long time, it’s possible that the sensor on the measure post is not properly aligned anymore.When this is the case, this document can be followed to align the sensors again. |

1. Use following tools

|

|

2. Procedure

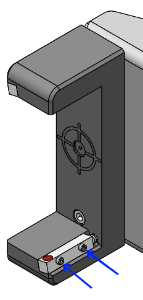

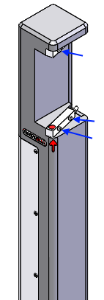

2.1. loosen the bolts

Loosen up the bolts, so you can move the sensors a little bit.

|

If you find it difficult to move the sensors, you can try and take the cable from the sensor out of the cable tray. |

2.2. Adjust receiver

Put the receiver in a straight position and tighten the receiver again.

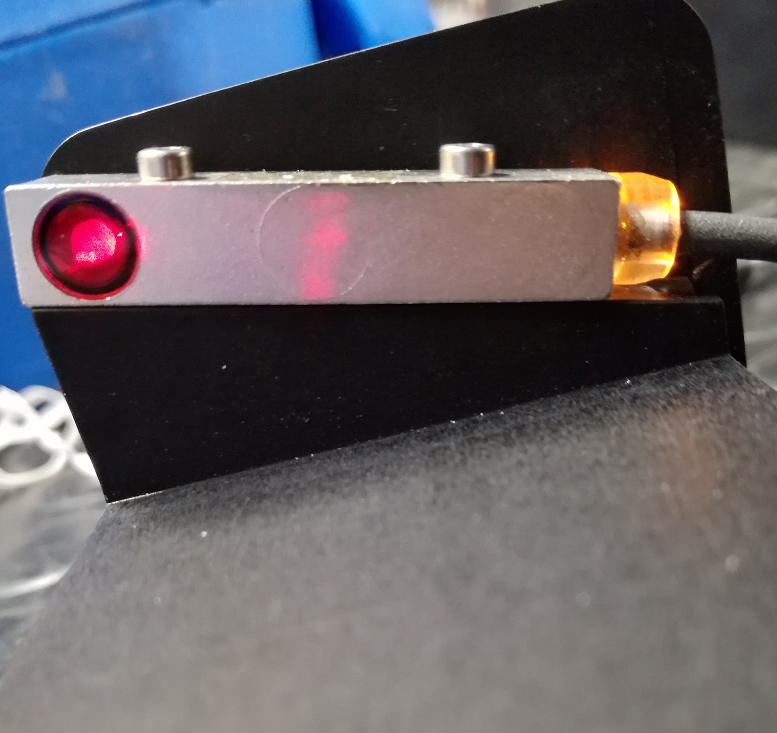

2.3. Align the emitter

Align the emitter perfectly straight with the receiver.So that the red dot of the emitter is straight in the middle of the red circle from the receiver.You’ll see that there will be an orange led lighting up when the laser dot is in the middle of the receiver.

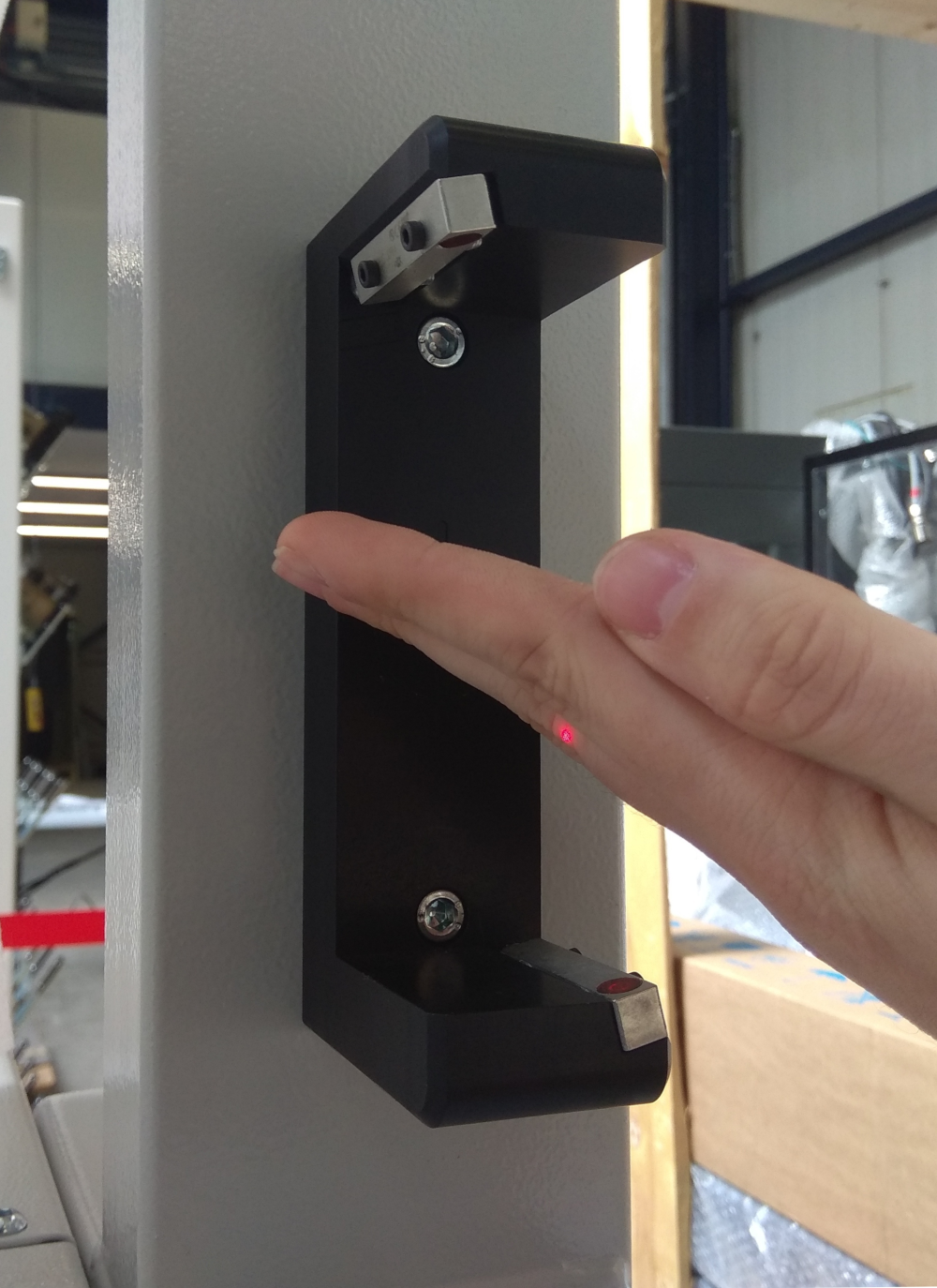

2.4. Testing

Go with your hand (or an object) a few times through the sensors and see if the LED on the receiver lights up accordingly.If your hand is between the sensors, the LED should be off and when there is no obstruction between the sensors, the LED should light up orange.

3. How to get further help

Do not hesitate to contact us when you need additional support beyond the documents provided in the RoboJob Service Knowledge Base.

You may contact the RoboJob Service department using following means:

-

Help Center: service.robojob.eu

-

Email: service@robojob.eu

-

Phone: +32 15 70 89 70

We kindly ask you to provide us the following information:

-

Serial number xx-xx-xxx

-

Description of the fault or defective part

-

Exact error code or message

-

What did the robot do

-

What was the robot supposed to do

-

Pictures or videos

You can send this information to us via email.To send large files you may make use of a file transfer service like WeTransfer: robojob.wetransfer.com.

An automatic confirmation will be sent upon receipt of your mail.